Standing Seam

Metal Manufacturer & Metal Fabricating Company

Metal Roofing

Custom built metal roofing products like drip edge, flashing, and fascia.

High Quality Metal

We can work with aluminum, copper, and even steel.

Roof Panel Machines

We have the gears and rollers for multiple types of roof paneling machines.

Fabrication and Finishing

Let us know if you need special considerations for your project.

Vortex Metal Fabrication: Home » Metal Roofing »

Roof Metal Manufacturing

Our metal procurement process involves obtaining coils, enabling us to manufacture panels of varying lengths, similar to the functionality of seamless gutters. All our metal coils are customized to meet specific requirements, including specifications, quantity, and color preferences. In most cases, we can also place orders for flat sheet metal in matching colors, allowing us to fabricate additional roofing components, ensuring a thorough completion of the project and a watertight roof.order flat sheet metal of the same color to fabricate any other roofing metal components to ensure a completed job and a roof that does not leak.

Metal Manufacturing Products

Metal Sheets Sheared

Linear Feet of Metal Finished

Benefits of Metal Roofing Products and Systems

Pros of Standing Seam Metal Roofs

Durability:

Standing seam metal roofs are highly durable and can withstand extreme weather conditions, including heavy rain, snow, and hail.

Longevity:

These roofs have a long lifespan, often exceeding 50 years, making them a cost-effective investment in the long run.

Low Maintenance:

With standing seam metal roofs, they require minimal maintenance, with occasional inspections and cleaning being sufficient to keep them in excellent condition.

Energy Efficiency:

Metal reflects sunlight, helping to reduce heat absorption and energy costs. Many standing seam roofs are ENERGY STAR certified for their energy-efficient properties.

Versatility:

Available in a variety of colors and finishes, standing seam metal roofs offer versatility in design, allowing homeowners to choose a style that complements their aesthetic preferences.

Fire Resistance:

Metal is inherently fire-resistant, providing an added layer of safety to the structure.

Cons of Standing Seam Metal Roofs

Installation Complexity:

Installation should be done by experienced professionals, and the complexity of the process may result in higher labor costs.

Expansion and Contraction:

Metal expands and contracts with temperature changes, and if not installed properly, this movement can lead to noise issues, such as popping sounds.

Denting Risk:

While standing seam roofs are resilient, they are not entirely impervious to dents, especially from heavy impacts like falling branches or hail.

Limited DIY Options:

Due to the precision required in installation, standing seam metal roofs are not suitable for DIY projects, limiting options for cost-conscious homeowners who prefer to do their own installations.

Standing Seam Engagement Methods

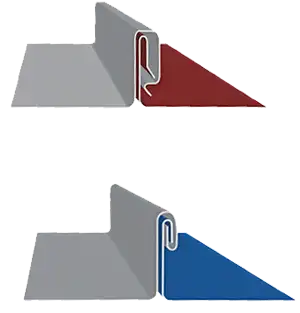

Snapped Standing Seam

Snapped panel systems feature a combination of male and female legs. Once these legs are securely joined, applying pressure causes the panels to snap together seamlessly, completing the installation sequence.

Mechanically Seamed

To ensure optimal performance, mechanically seamed systems necessitate the utilization of a powered seaming machine post-panel installation.

Standing Seam Attachment Methods

Clipless Standing Seam

Clipless standing systems secure themselves through a pre-punched fastening flange. These flanges usually feature recurring slots spaced every 2-4 inches, streamlining the attachment process to the roofing deck, commonly constructed with plywood.

Clipped Standing Seam

Clipped systems consist of a clip that is integrated into the male/female panel legs and is then attached to the deck or purlins.