Plasma Cutting

We have a full scale plasma cutting table that allows us to plasma torch full sheets of steel. Our table allows us to cut 4′ x 10′ and up to a 1/4″ thick steel as well as aluminum or copper. Furthermore you can learn more about our powder coating process if it is required for your project.

Metal Manufacturer & Metal Fabricating Company

Metal Fabrication

Custom built projects for residential or commercial services.

High Quality Metal

We can work with aluminum, copper, and even steel.

Delivery Available

We can ship and deliver to most of the lower 48 states.

Fabrication and Finishing

Let us know if you need special considerations for your project.

Vortex Metal Fabrication: Home » Metal Manufacturing »

Plasma Table Cutting Torch

Plasma cutting torch tables, also known as plasma cutting tables or CNC plasma cutting tables, are specialized tools used in our metal fabrication and industrial applications. These tables provide a precise and efficient method for cutting various types of metal using a plasma cutting torch.

The CNC system is programmed with the desired cutting pattern, allowing for accurate and repeatable cuts. The plasma cutting torch generates a high-temperature plasma arc that melts through the metal, while a high-velocity gas stream blows away the molten material.

Metal Manufacturing Products

Metal Sheets Sheared

Linear Feet of Metal Finished

How Plasma Cutting Torches Work

A plasma torch works by utilizing the principles of plasma, which is a state of matter that occurs when a gas is heated to extremely high temperatures. By combining extreme heat and a focused gas stream, a plasma torch can effectively cut through a variety of conductive materials, including steel, stainless steel, aluminum, and copper. Its versatility, speed, and precision make it a popular tool in industrial applications that require efficient metal cutting.

Here’s a simplified explanation of how a plasma torch operates.

- Gas Supply: A gas, typically compressed air or a mixture of gases, such as oxygen and nitrogen, is supplied to the torch.

- Electrical Arc: An electric arc is created between the torch’s electrode (cathode) and the nozzle (anode). The arc provides the energy required to heat the gas and initiate the plasma formation.

- Ionization: The electric arc ionizes the gas, stripping electrons from the gas atoms and creating a plasma. Plasma is an ionized gas consisting of positively charged ions and negatively charged electrons.

- Plasma Jet: The high-energy plasma forms a plasma jet, which is forced through a small orifice in the torch nozzle. The plasma jet reaches temperatures of up to 30,000 degrees Celsius (54,000 degrees Fahrenheit).

- Cutting Action: When the plasma jet contacts the metal workpiece, the intense heat melts the metal in its path. Simultaneously, a high-velocity gas, usually compressed air, blows away the molten material, creating a cut.

- Torch Movement: The plasma torch is moved along a predetermined path, guided by a CNC system in the case of a CNC plasma cutting table. This allows for precise and controlled cutting, following the desired shape or pattern.

Metal Manufacturing Colors

We offer a wide range of manufacturers colored steel products. Drexel metals, MPI, & CMG are just a few of the colors we have available. If we do not have a color you see on our colors page then feel free to reach out and we will order the necessary colors.

Otherwise feel free to check out our store. Sometimes we have excess sheets of metal that we sell at cost or discount so make sure to check back often.

Call For a Quote:

(402) 310-4469

Latest Metal Manufacturing Projects

Copper Roofing Panels

A small roofing project that has copper roofing panels and copper edge metal.

Plasma Cut Steel

We cut some roof anchors and roof safety plates on our CNC plasma cutter.

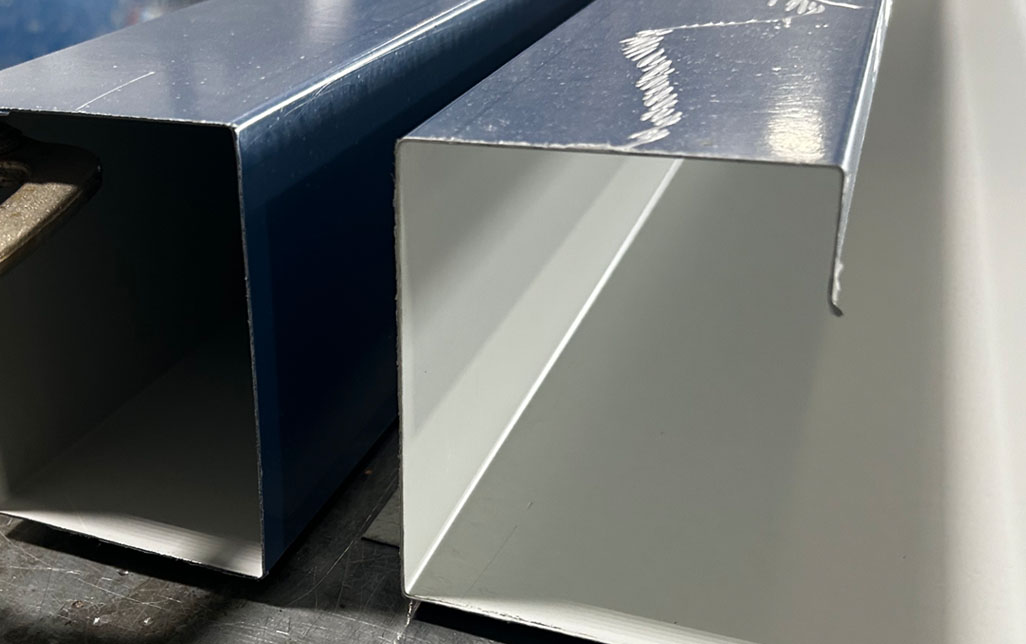

Gutters & Downspouts

We were contracted to fabricate edge metal, fascia, gutters, downspouts, and more.